Oil-Free Turbo Compressor

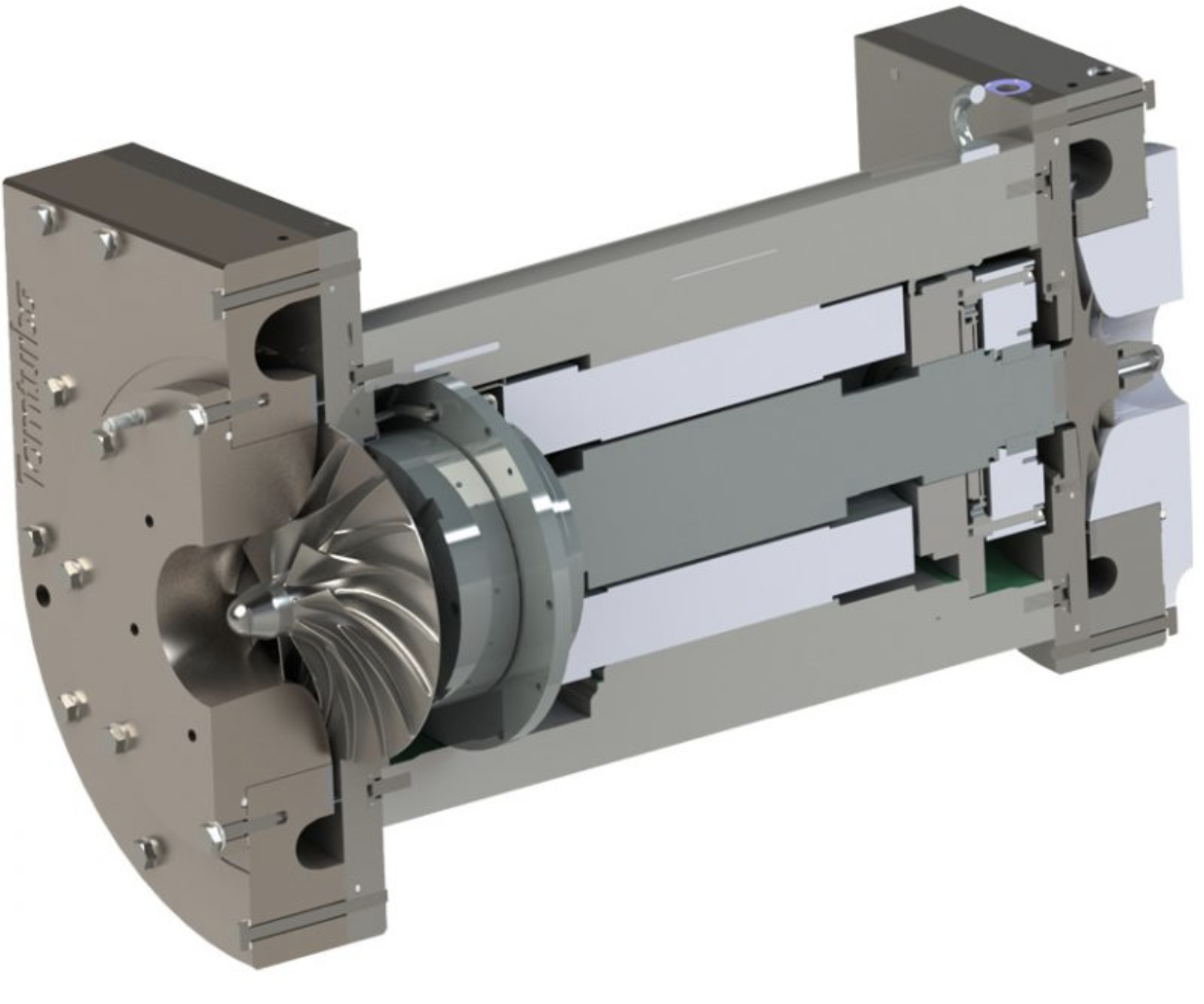

The Tamturbo® Touch-Free™ series is a variable speed drive (VSD) turbo compressor that, thanks to magnetic bearing technologies, produces completely oil-free compressed air for industrial applications while eliminating the need for maintenance altogether.

TAMTURBO® Turbo Compressors – NO FRICTION. NO OIL. NO PROBLEMS.

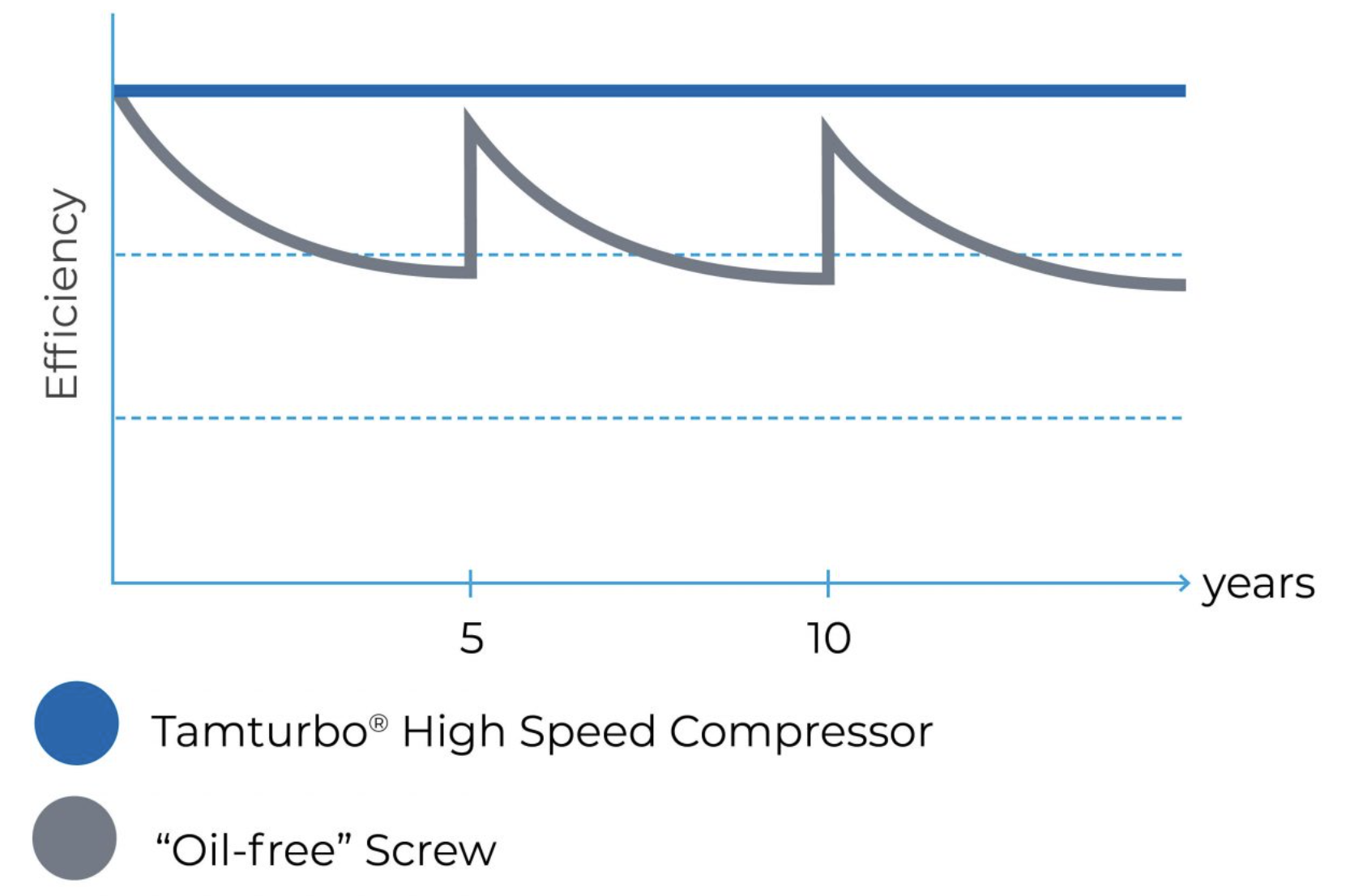

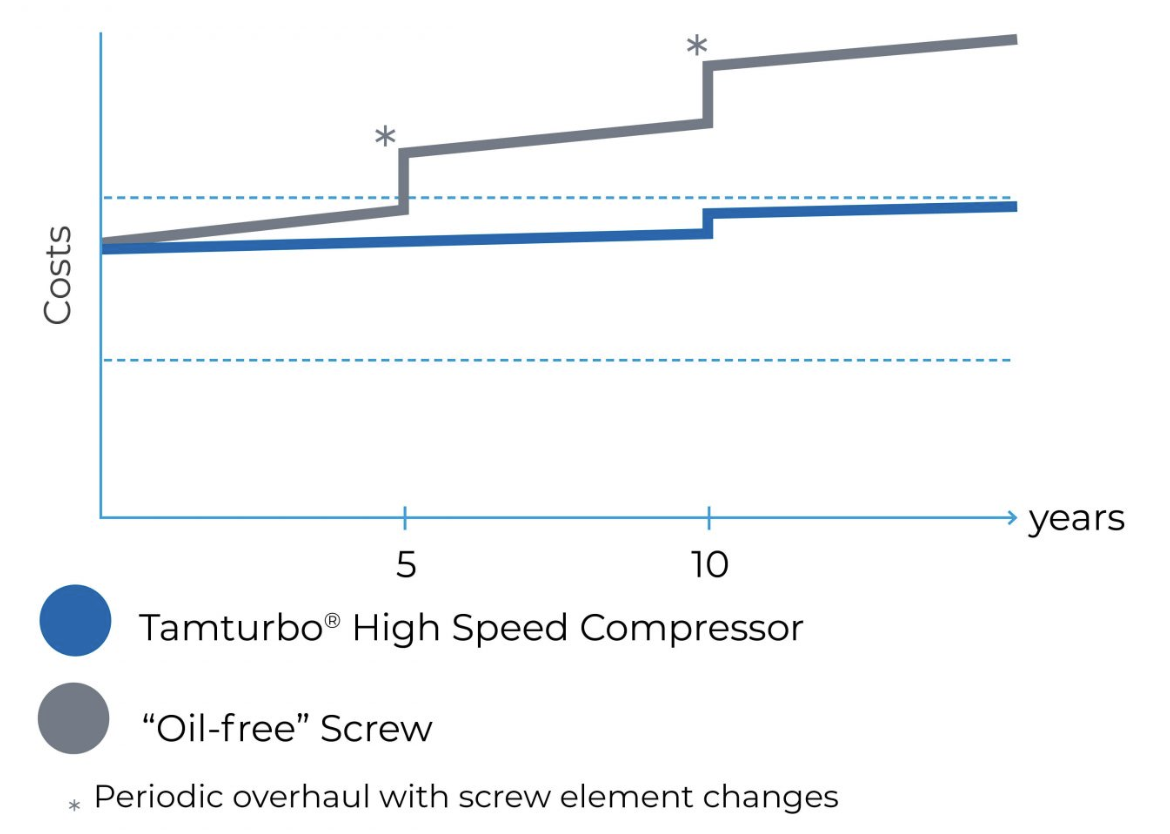

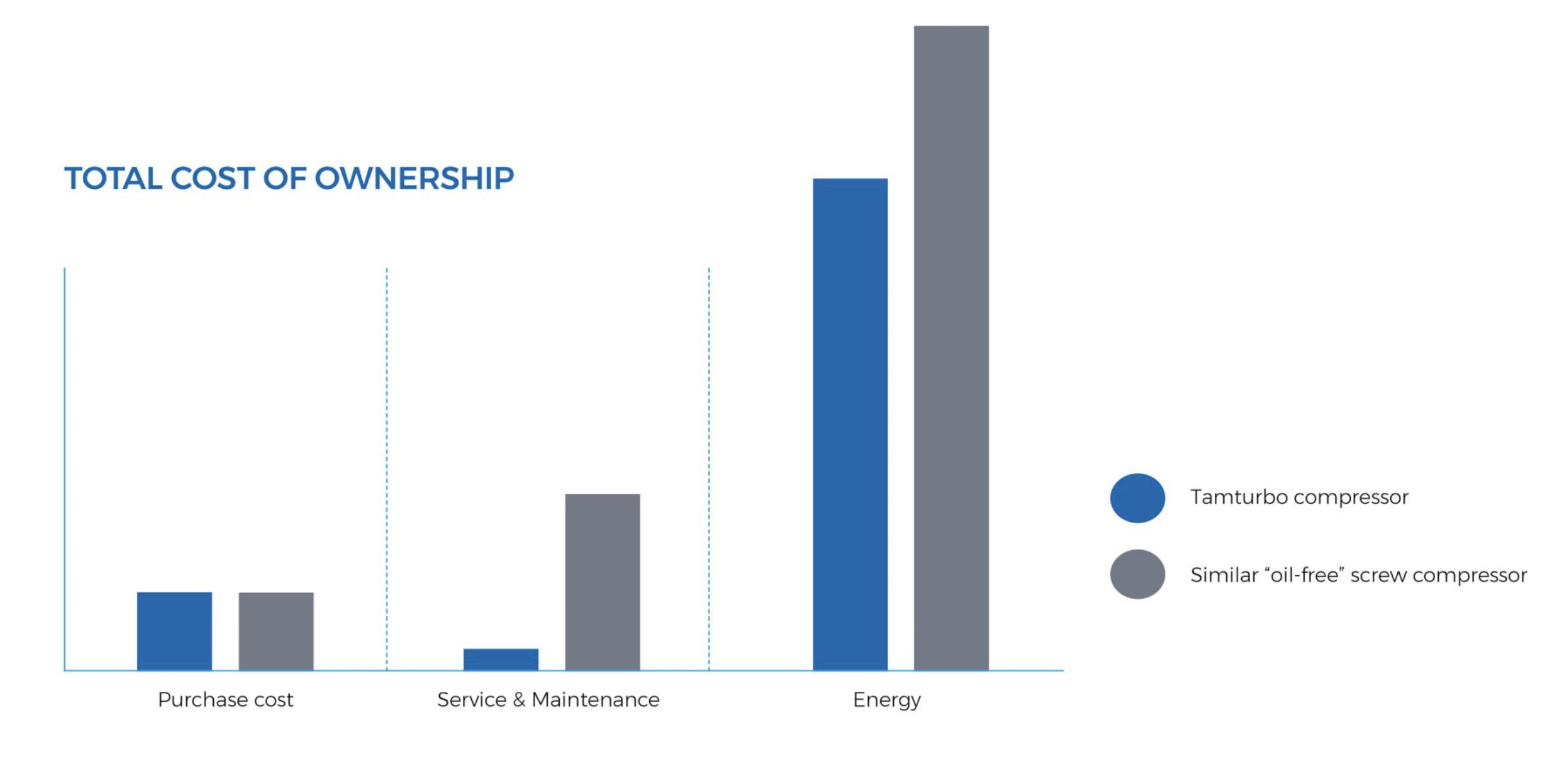

Touch-Free™ variable speed drive (VSD) turbo compressors provide high-efficiency compressed air production, offering significant energy savings. This delivers substantial financial benefits to businesses through lower costs while reducing environmental impact thanks to decreased energy consumption.

Tamturbo’s patented Touch-Free™ technology completely eliminates component wear and maintenance requirements. Thanks to this technology, users can significantly reduce periodic maintenance intervals and costs, while extending the technical service life of the equipment. Less downtime and longer operational life also contribute to reducing environmental waste.

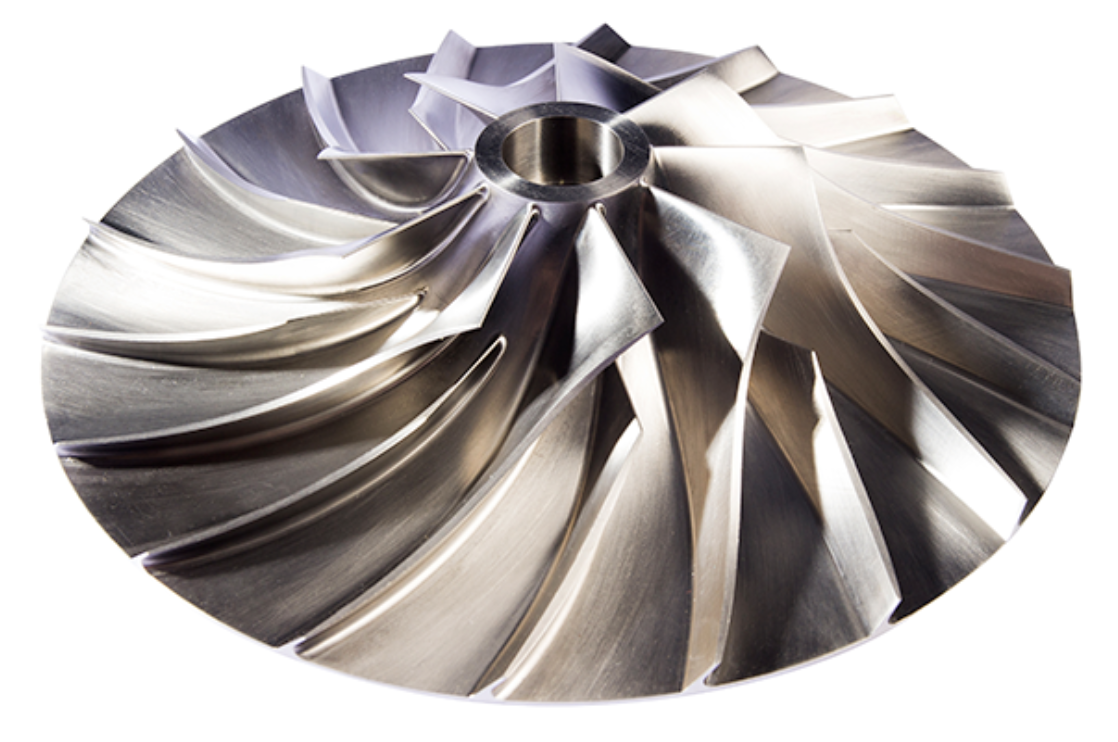

High-speed turbo compressors produce 100% oil-free compressed air. Moreover, not only the air output but the entire compressor system is completely oil-free. This fully removes the risk of oil contamination on products or in the working environment. As a result, businesses are entirely freed from tasks such as oil changes, oily condensate separation, or waste oil disposal.

Tamturbo eliminates the need for oil altogether. This means not only easier maintenance but also hygiene, sustainability, and reliability in production processes.

100% Oil-Free Compressed Air: Zero Risk of Contamination

Tamturbo® produces 100% oil-free air. It completely eliminates all risks of oil contamination in compressed air.

Did you know? A typical “oil-free” rotary screw compressor actually contains about 60 liters (15 gallons) of oil.

Just focus on your production

The high reliability of Tamturbo® VSD turbo compressors ensures minimal planned and unplanned downtime, along with easy predictability of preventive maintenance needs. This provides your business with smooth and uninterrupted compressed air supply, allowing you to focus on your production and dedicate your energy to your work.

No Contact, No Wear

RELIABILITY: Rotating parts are magnetically suspended in the air, contacting only the air – mechanical contact is zero.

PRECISION: Thanks to an active measurement and control system, the rotating parts are always held in place with millimeter accuracy.

GAP CONTROL: Gap structure designed with precise tolerances to facilitate maintenance.

DURABILITY: Unlimited start-stop capability. No risk of damage even during power outages.

Frequently Asked Questions

Learn about the Inverter Turbo Compressor.

Tamturbo VSD compressors deliver significant energy savings through their high energy efficiency, providing both economic benefits to customers and positive environmental impact. Thanks to Touch-Free™ technology, maintenance requirements are eliminated, which reduces maintenance costs and extends equipment lifespan, thereby minimizing waste generation. Additionally, their completely oil-free design removes any risk of air contamination, ensuring product quality and a safe working environment. Customers are freed from additional tasks such as oil changes and oily condensate management.

Tamturbo’s oil-free, variable speed drive (VSD) compressors stand out with their energy efficiency and low maintenance costs.

Our products are preferred in many industries, especially manufacturing, textile, electronics, automotive, pharmaceutical and medical, paper and pulp, and food and beverage sectors.

“On-Demand Service” Advantage in Tamturbo VSD Compressors

Tamturbo VSD compressors are serviced only when necessary, preventing unnecessary downtime and costs.

There is no hourly routine or periodic maintenance requirement. Thanks to its design and technology, many potential failure parts (gears, bearings, seals, oil separators, oil pumps, filters, and oil) have been removed from the system. This minimizes the risk of breakdowns and ensures uninterrupted operation of your business.

Thanks to inverter technology, Tamturbo compressors automatically adjust motor speed according to demand. This optimizes energy consumption and reduces operating costs. Additionally, total efficiency can be enhanced with extra features such as energy recovery.

Tamturbo®’s proprietary Active Magnetic Bearings (AMB) form the foundation of Touch-Free™ technology. These frictionless, contact-free bearings ensure that components never wear out or fail. The AMBs respond instantly to eliminate vibration completely. Additionally, the magnetic levitation system protects against damage during potential power outages at your facility; the energy stored in the rotating parts and capacitors sustains the bearings until the motor slows down and stops. Hundreds of thousands of AMB units used in demanding environments such as HVAC, oil and gas fields, and deep-sea gas pumps demonstrate the technological maturity, reliability, and superiority of our product.

We Support Your Business with High-Quality Products and Services Worldwide

Optimize your operations with our compressed air solutions that adapt to evolving industrial needs, and stay ahead of the competition by increasing your efficiency.

Since 1969, our family-owned company—now in its third generation—has specialized in industrial filtration and compressed air, delivering the most reliable solutions in the industry to meet business needs at the highest level. With our Istanbul-based operations and robust logistics network, we provide fast and efficient service to customers across Turkey.

Compressed Air

Measurement, Control, and Detection Devices

Compressors

Air Treatment Units

Dust Collection Systems

Filter Group

Tepeören Mah. İTOSB 14th Street No:2 34959 Tuzla / ISTANBUL

Monday – Friday 08:30 AM – 06:30 PM

+90 216 661 40 44

[email protected]