Thermal Probe Flowmeter

The VPFlowScope® Thermal Mass Probe, suitable for dry and clean air and used after dryers and filters, is a flow measurement device designed for compressed air, nitrogen, carbon dioxide, argon, and other technical gases.

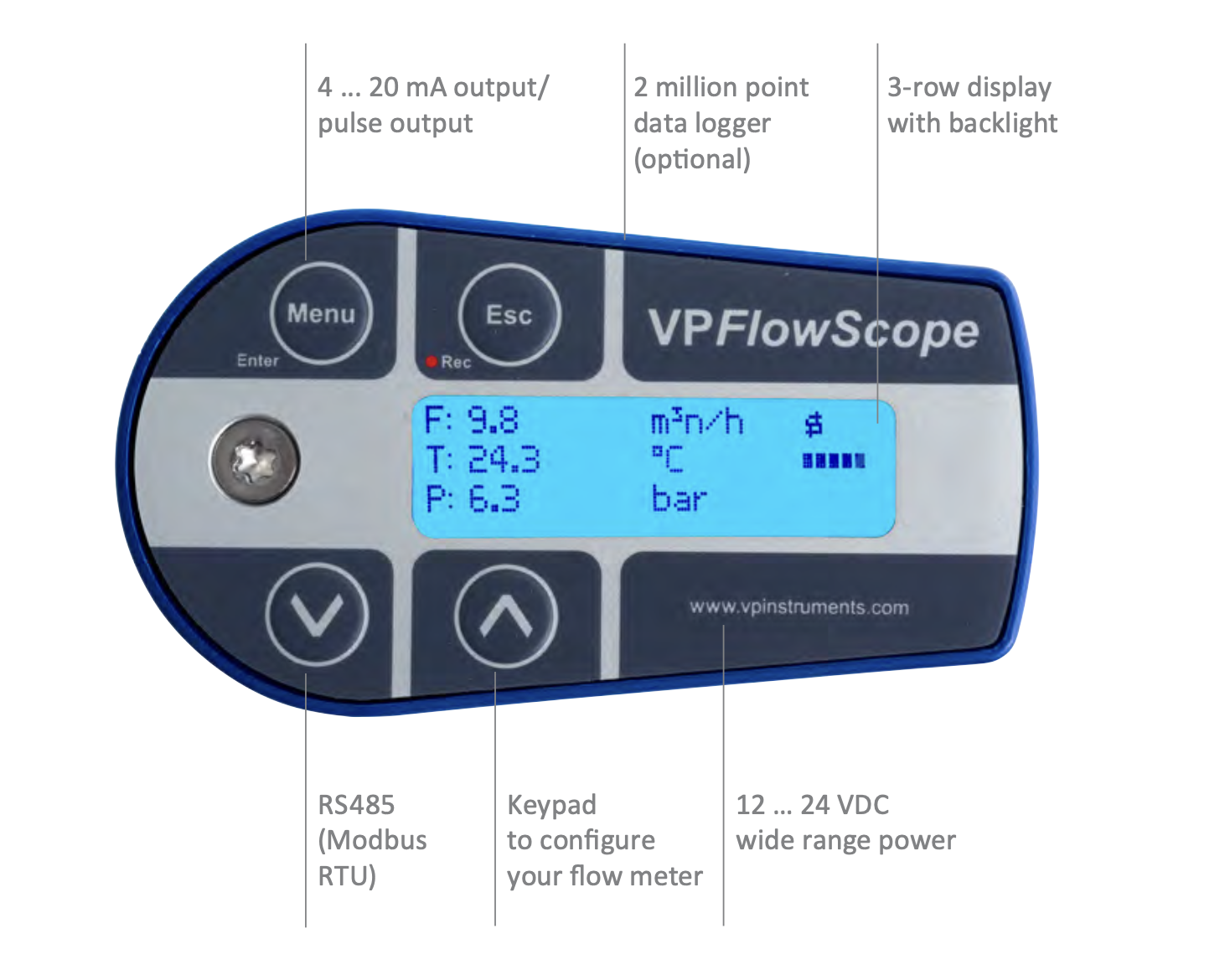

The VPFlowScope Probe can simultaneously measure thermal mass flow, pressure, temperature, and total flow.

VPFlowScope Thermal Probe

The VPFlowScope Thermal Probe can be used with various pipe diameters (above 2 inches); this feature makes it an ideal solution for measuring both the production (supply) and consumption sides of compressed air systems.

The flow meter shows where, when, and how much air is used, helping to allocate costs accurately and thereby enabling energy and cost savings.

Thanks to its bright blue LCD screen, it provides instant (real-time) information. With the built-in data logger, measurements can be recorded at specified intervals. When used together with a SCADA system, these data can be processed, reports can be generated, and analyses can be made on where and how savings can be achieved.

Features

• 4-in-1 sensor: Instantaneous flow, pressure, temperature, and total flow measurement

• Bidirectional flow measurement (optional)

• Patented Thermabridge™ technology: Provides precise measurement for dry and clean gases

• Standard outputs: RS485, 4..20 mA, and ANALOG (pulse) output

• 3-line LCD display (optional): Usage with real-time data and configuration buttons

• Built-in data logger (optional): Storage capacity of 2 million data points

Applications and Advantages

• Suitable for dry air after dryers and filters

• Compressed air monitoring at consumption points

• Compressed air audits

• Monitoring compressed air with submeters

• Use in ring-type piping systems (advantage of bidirectional measurement)

• Monitoring industrial gases: air, nitrogen, carbon dioxide, argon, and other dry, non-corrosive gases

• Cost allocation and tracking

• Leak detection

• Available in 16 bar (250 psi) and 35 bar (500 psi) operating pressure options (for compressed air systems)

FLOW SENSOR

• Measurement Principle: Thermabridge™ Thermal Mass Method

• Flow Range: 0.5 … 150 m/s | 1.7 … 490 sfps, bidirectional measurement option

• Recommended Pipe Diameter: 40 mm (1.5”) and above

• Reference Conditions: 0 °C, 1013.25 mbar, 14.65 psi – DIN 1343

• Suitable Gases: Compressed air, nitrogen, and inert, non-condensing gases; up to 95% non-condensing gases

• Gas Temperature Range: 0 … 60 °C

PRESSURE SENSOR

• Pressure Range (standard): 0 … 16 bar

• Accuracy: ±0.15%

TEMPERATURE SENSOR

• Temperature Range: 0 … 60 °C

• Accuracy: > 10 m/s: ±1 °C; < 10 m/s: ±5 °C

DATA OUTPUTS

• Digital Output: RS485, MODBUS RTU protocol

• Analog Output: 4 … 20 mA, single analog output, configurable via VPStudio software

DATA LOGGER

• Data Logger (optional): 2 million data points memory

MECHANICAL & ENVIRONMENTAL

• Probe Lengths: 400 mm | 15” (optional 300 mm or 600 mm)

• Process Connection: Compression fitting, 0.5” NPT thread

• Pressure Resistance: PN16 (optional PN35), 16 BAR (can be increased optionally)

• Protection Class (IP):

• IP52 | NEMA 12 (when display module attached, avoid inverted installation)

• IP63 | NEMA 4 (when connector cover attached, avoid inverted installation)

• Ambient Temperature Range: 0 … 60 °C (avoid direct sunlight and radiant heat)

• Wetted Materials: Anodized aluminum, stainless steel 316, glass, and epoxy

• Corrosion Resistance: Avoid highly corrosive or acidic environments

ELECTRICAL

• Connection Type: M12, 5-pin connector, female

• Power Supply: 12 … 24 VDC, Class 2 (UL)

• Power Consumption:

• 3.6 W (no flow), 4.8 W (full flow)

• 150 mA (no flow), 200 mA (full flow) - 24VDC

CERTIFICATIONS

UL / CUL: 14 AZ, Industrial Control Equipment

CE: EN 61325-1 (2006), Class A EN 61000-6-1 (2007)

We Support Your Business with High-Quality Products and Services Worldwide

Optimize your operations with our compressed air solutions that adapt to evolving industrial needs, and stay ahead of the competition by increasing your efficiency.

Since 1969, our family-owned company—now in its third generation—has specialized in industrial filtration and compressed air, delivering the most reliable solutions in the industry to meet business needs at the highest level. With our Istanbul-based operations and robust logistics network, we provide fast and efficient service to customers across Turkey.

Compressed Air

Measurement, Control, and Detection Devices

Compressors

Air Treatment Units

Dust Collection Systems

Filter Group

Tepeören Mah. İTOSB 14th Street No:2 34959 Tuzla / ISTANBUL

Monday – Friday 08:30 AM – 06:30 PM

+90 216 661 40 44

[email protected]