M Flow Meter

The VPFlowScope M is a flow meter designed for compressed air and technical gases that performs four measurements (pressure, temperature, flow, total flow) in one device.

It can be installed under pressure and simultaneously measures flow, pressure, temperature, and total flow.

The VPFlowScope M requires no calibration; its cartridge can be replaced without interrupting usage or sending the device for recalibration. In other words, unlike traditional flow meters, there is no need to return the device for recalibration. Thanks to its no calibration technology, you can change the cartridge in seconds and continue using it.

Instead, the device consists of two main components: a transmitter and the patented VPSensorCartridge®. This design allows the calibration process to be easily completed in the field by swapping the cartridge. Additionally, this method helps reduce your Scope 3 emissions.

VPFlowScope M Flow Meter

Learn detailed information about the VPFlowScope M Flow Meter.

Features

• Ethernet (Modbus/TCP)

• RS485 (Modbus RTU)

• 4..20 mA, alarm or analog output

• Configuration and data log file download via USB interface

• Optional display for real-time data viewing, with the ability to monitor 1, 2, or 3 parameters simultaneously

• Seamless integration with VPVision monitoring platform or your SCADA system

• Optional integrated data logger for audits, synchronizable

Applications and Advantages

• No calibration required

• Suitable for use after dryer and filter

• Monitoring and flow measurement of compressed air on consumption and production sides

• Compressed air audits

• Bidirectional measurement

• Industrial gas monitoring (air, nitrogen, carbon dioxide, argon, and other dry, non-corrosive industrial gases)

• Leak detection

FLOW SENSOR

• Measurement Principle: Thermabridge™ Thermal Mass Method

• Flow Range: 0 (0.5) … 150 m/s

• Bidirectional Flow: Optional, see product codes

• Accuracy: ±2% of reading under calibration conditions

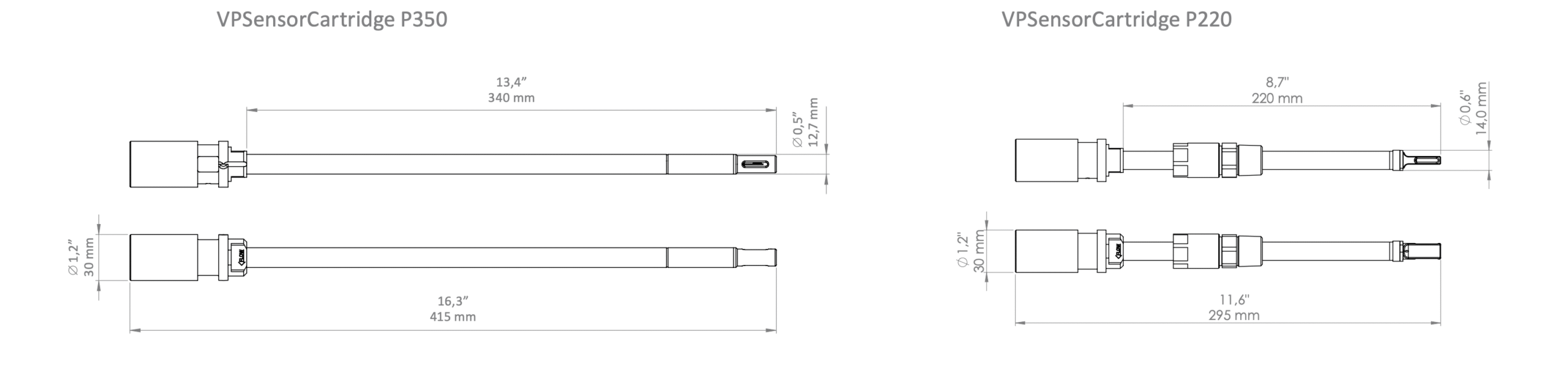

• Recommended Pipe Diameter: 1 … 2.5” (P220) and 1 … 20” (P350)

• Reference Conditions: 0 °C, 1013.25 mbar

• Suitable Gases: Compressed air, nitrogen, and inert, non-condensing gases

• Gas Temperature Range: 0 … +60 °C

PRESSURE SENSOR

• Pressure Measurement Range: 0 … 10 bar (P350) / 0 … 16 bar (P220)

• Accuracy: ±0.1% FSS (total error band), temperature compensated

TEMPERATURE SENSOR

• Temperature Range: 0 … +60 °C

MECHANICAL & ENVIRONMENTAL

• Probe Lengths: 340 mm | 220 mm

• Weight: 200 grams (P350) / 246 grams (P220, including safety ring)

• Process Connection: Compression fitting, 1/2” NPT, tapered (P350) / O-ring sealed connection, NBR (P220)

• Pressure Resistance: P350: PN10 / P220: PN16

• Protection Class: IP65 | NEMA 4 when used with transmitter

• Operating Ambient Temperature: 0 … +60 °C

• Housing Material: Anodized Aluminum, Stainless Steel 316, Glass, Epoxy

• Corrosion Resistance: Avoid highly corrosive environments

• Ball Valve: DN15 full bore ball valve required for P220. Larger valves should be used with reduction.

DISPLAY

• Display Type (D010 and D011): 1.8” TFT screen, automatic power saving (optional)

• LED Indicators (All Models): LEDs for power, communication, and alarm status

• Data Logger: 1-year memory, 1 record per second

OUTPUTS

• RS485: Modbus RTU

• Analog / Digital Output: 4 … 20 mA, alarm output (configurable)

• USB: Mini USB (for configuration), behind a sealed cover

• Ethernet: Modbus / TCP

MECHANICAL & ENVIRONMENTAL

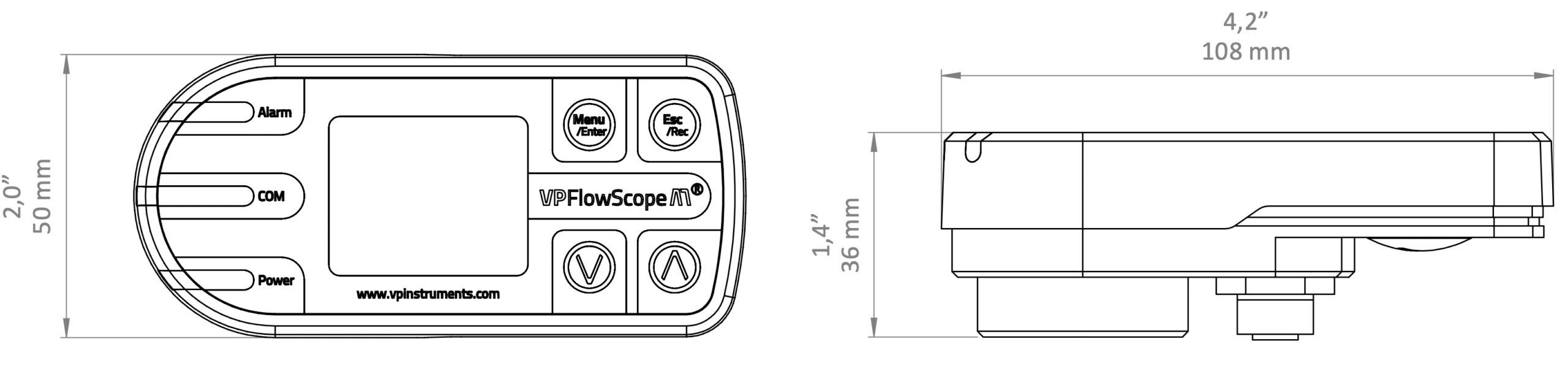

• Dimensions: 50 x 108 x 36 mm

• Weight: 220 grams

• Material: Anodized aluminum housing, polycarbonate cover

• O-ring Seals: NBR

• Protection Class: IP65 | NEMA 4 (when VPSensorCartridge® installed and USB cover secured)

ELECTRICAL

• Power Supply: 14 … 24 VDC +10%, CLASS 2 (UL)

• Connections: Power / RS485 / 4 .. 20 mA: M12, 5-pin

• Ethernet: M12, 4-pin, D-coded

• Power Consumption: 1 Watt (no flow), 3.5 Watt (maximum flow)

CERTIFICATIONS

• CE: EN 60950-1, EN 61326-1, EN 61000-3-2, EN 61000-3-3, EN 61326-1

• UL: UL 508

We Support Your Business with High-Quality Products and Services Worldwide

Optimize your operations with our compressed air solutions that adapt to evolving industrial needs, and stay ahead of the competition by increasing your efficiency.

Since 1969, our family-owned company—now in its third generation—has specialized in industrial filtration and compressed air, delivering the most reliable solutions in the industry to meet business needs at the highest level. With our Istanbul-based operations and robust logistics network, we provide fast and efficient service to customers across Turkey.

Compressed Air

Measurement, Control, and Detection Devices

Compressors

Air Treatment Units

Dust Collection Systems

Filter Group

Tepeören Mah. İTOSB 14th Street No:2 34959 Tuzla / ISTANBUL

Monday – Friday 08:30 AM – 06:30 PM

+90 216 661 40 44

[email protected]