Compressor Performance Measurement

Compressors operating with high energy consumption in industrial facilities can lead to significant energy losses during compressed air production. Compressor performance measurement is a critical step to improve energy efficiency and prevent unnecessary costs.

Compressor performance measurement helps determine optimal operating conditions by analyzing energy consumption, flow rate, and system efficiency. These measurements prevent unnecessary energy losses and provide significant cost savings for businesses.

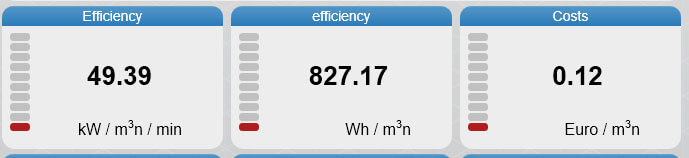

For compressors to operate efficiently, flow rate, pressure, and energy consumption must be measured regularly. Measurement results help identify system components that consume excessive energy or operate inefficiently. In particular, monitoring pressure losses and dew point values in compressed air dryers helps prevent potential energy losses in the system. Additionally, determining the efficiency coefficient ensures that compressors operate at optimal capacity. As a result of these analyses, energy consumption is reduced, system performance is improved, and operational costs are significantly lowered.

Measuring Compressor Energy Consumption with a Current Sensor

Measuring the energy consumption of a compressor using a current sensor is highly important in terms of energy efficiency. To determine the compressor's efficiency, energy consumption measurements must be carried out in a reliable and accurate manner.

Sample Compressor Performance Graph

In compressor performance measurements, we use moisture-resistant flow meters to accurately measure flow rate, temperature, and pressure values. By analyzing the data obtained, we prepare reliable and detailed reports that assess the efficiency of the system. With these reports, businesses can optimize energy consumption, identify potential losses, and manage their compressed air systems in the most efficient way.

The Importance of Compressor Performance Measurement

Compressors are critical equipment in industrial facilities that consume large amounts of energy to produce compressed air. However, inefficiently operating compressors can consume excessive energy, increasing operational costs. Compressor performance measurement helps determine how efficiently the system operates by analyzing key parameters such as flow rate, pressure, and temperature. In this way, energy losses can be identified and addressed, unnecessary consumption can be prevented, and the system can be maintained at optimal performance. With accurate and regular measurements, businesses can reduce costs through energy savings and establish a more sustainable production process.

Determining Compressor Efficiency

Efficient operation of compressors is crucial for reducing energy costs and establishing sustainable production processes in businesses. Through performance measurements, the energy consumption, generated air flow, pressure levels, and temperature values of each compressor are analyzed to evaluate efficiency. The collected data is interpreted by considering factors such as the compressor’s operating principle, control system, and load variations. Based on the measurement results, inefficiencies caused by the compressor’s operating regime are identified, and improvement suggestions are provided. These analyses help determine the energy saving potential, enabling businesses to achieve higher performance at lower costs.

Measuring Compressed Air Consumption in the Facility

Effective management of compressed air systems in industrial facilities is a critical factor for increasing energy efficiency and reducing operational costs. Measuring compressed air consumption enables accurate determination of the system’s air demand and helps prevent unnecessary energy use. Through these measurements, the consumption profile is analyzed to identify how much air is used in which processes, revealing issues such as excessive consumption or irregular airflow. When necessary, system optimization can be carried out by implementing measures such as leak detection, pressure level adjustments, and the use of more efficient equipment. Additionally, regularly monitoring compressed air consumption supports businesses in achieving their sustainability goals and minimizing environmental impact. As a result, energy savings are achieved while reducing the facility’s carbon footprint and promoting an environmentally friendly production process.

Measurement of Dryer Performance and Compressed Air Moisture Analysis

In compressed air systems, the efficient operation of air dryers is essential both for achieving energy savings and maintaining process safety. Measuring the moisture content in compressed air at the dryer outlets helps evaluate the drying capacity of the system. Additionally, determining the energy consumption values and measuring pressure differentials—especially for refrigerated and chemical dryers—are critical parts of the assessment process.

As part of air dryer performance measurements, dew point values are analyzed to monitor the operating status of the dryers and assess their efficiency. During this process, necessary optimization measures are implemented to prevent the system from consuming excessive energy. Through regular maintenance and performance checks, dryers are ensured to operate in an energy-efficient manner, enabling businesses to reduce costs and establish a more sustainable production process.

Frequently Asked Questions

Learn more about compressor performance measurement.

Compressor performance measurement enables the optimization of energy consumption, ensures efficient operation of compressed air systems, and helps prevent unnecessary energy losses. Through these measurements, the operating regime of compressors is evaluated, potential savings opportunities are identified, and operational costs are reduced.

During the measurement process, data such as flow rate, pressure, temperature, energy consumption, and dew point are analyzed. Based on this data, the efficiency of the compressors is determined, and potential areas for improvement within the system are identified.

The frequency of measurement depends on the intensity of compressed air usage in the facility. In general, it is recommended to perform a comprehensive performance analysis at least once a year. However, in facilities with high energy consumption, conducting more frequent measurements can be beneficial for the early detection of potential inefficiencies.

We Support Your Business with High-Quality Products and Services Worldwide

Optimize your operations with our compressed air solutions that adapt to evolving industrial needs, and stay ahead of the competition by increasing your efficiency.

Since 1969, our family-owned company—now in its third generation—has specialized in industrial filtration and compressed air, delivering the most reliable solutions in the industry to meet business needs at the highest level. With our Istanbul-based operations and robust logistics network, we provide fast and efficient service to customers across Turkey.

Compressed Air

Measurement, Control, and Detection Devices

Compressors

Air Treatment Units

Dust Collection Systems

Filter Group

Tepeören Mah. İTOSB 14th Street No:2 34959 Tuzla / ISTANBUL

Monday – Friday 08:30 AM – 06:30 PM

+90 216 661 40 44

[email protected]