Automation and Inverter Applications

In industrial facilities, one of the highest points of energy consumption is the compressors that meet the air demand. The efficient operation of compressors has a significant impact on the overall energy efficiency of the facility.

Efficiency is measured by the amount of air (in m³) produced per kWh of energy consumed by a compressor. Therefore, it is essential to continuously monitor the output air flow of compressors in m³/hour (m³/h) and total m³, as well as to measure and record the electrical input in kW and kWh.

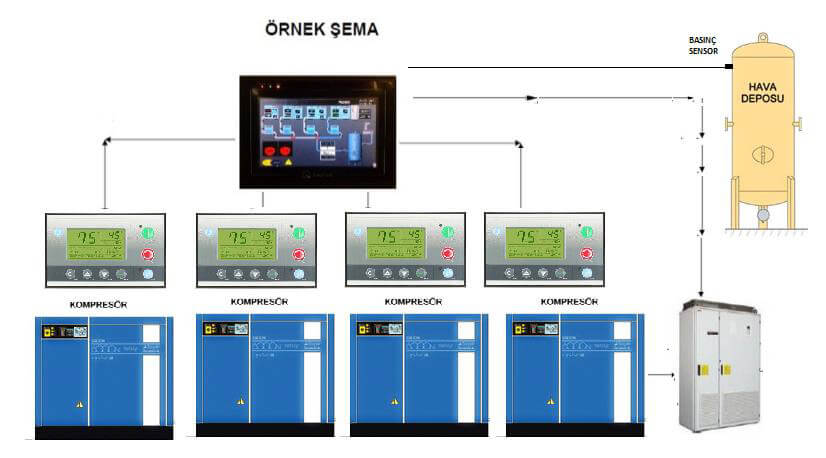

To enhance compressor performance and reduce energy costs, automation systems and inverter applications are employed. These solutions optimize the operating conditions of compressors, providing energy savings and increasing productivity.

Compressor Idle Running Prevention Solution

Idle running of compressors leads to significant electricity consumption. To reduce this unnecessary energy use, employing inverter-based compressors along with an integrated automation system can provide substantial savings. Inverters adjust the compressor speed according to the load demand, supplying only the required air flow. In this way, energy efficiency is increased while operational costs are reduced.

Energy Efficiency and Long-Term Savings

Automation systems and inverter-based compressor applications not only provide instant energy savings but also significantly reduce long-term operational costs. These efficiency-enhancing systems decrease maintenance time and extend equipment lifespan, improving the overall performance of the facility. The return on investment delivers savings far beyond the initial expenditure, making them a valuable tool in helping businesses achieve their sustainability goals.

Frequently Asked Questions

Learn more about automation and inverter applications.

Inverter-based compressors save energy by adjusting motor speed according to load conditions. This prevents unnecessary electricity consumption by producing only the required air flow. Additionally, reduced wear and tear extends the lifespan of the equipment.

Automation systems operate using software that monitors and controls the operating conditions of compressors. These systems detect air demand and automatically adjust the compressor's speed accordingly. In doing so, energy efficiency is increased and operational costs are reduced.

The installation process varies depending on the size of the facility and the integration of existing systems. Typically, the installation of automation and inverter applications can take anywhere from a few days to a few weeks. Our expert team works to complete the process as quickly and efficiently as possible.

We Support Your Business with High-Quality Products and Services Worldwide

Optimize your operations with our compressed air solutions that adapt to evolving industrial needs, and stay ahead of the competition by increasing your efficiency.

Since 1969, our family-owned company—now in its third generation—has specialized in industrial filtration and compressed air, delivering the most reliable solutions in the industry to meet business needs at the highest level. With our Istanbul-based operations and robust logistics network, we provide fast and efficient service to customers across Turkey.

Compressed Air

Measurement, Control, and Detection Devices

Compressors

Air Treatment Units

Dust Collection Systems

Filter Group

Tepeören Mah. İTOSB 14th Street No:2 34959 Tuzla / ISTANBUL

Monday – Friday 08:30 AM – 06:30 PM

+90 216 661 40 44

[email protected]