Compressed Air Piping Installation & Engineering

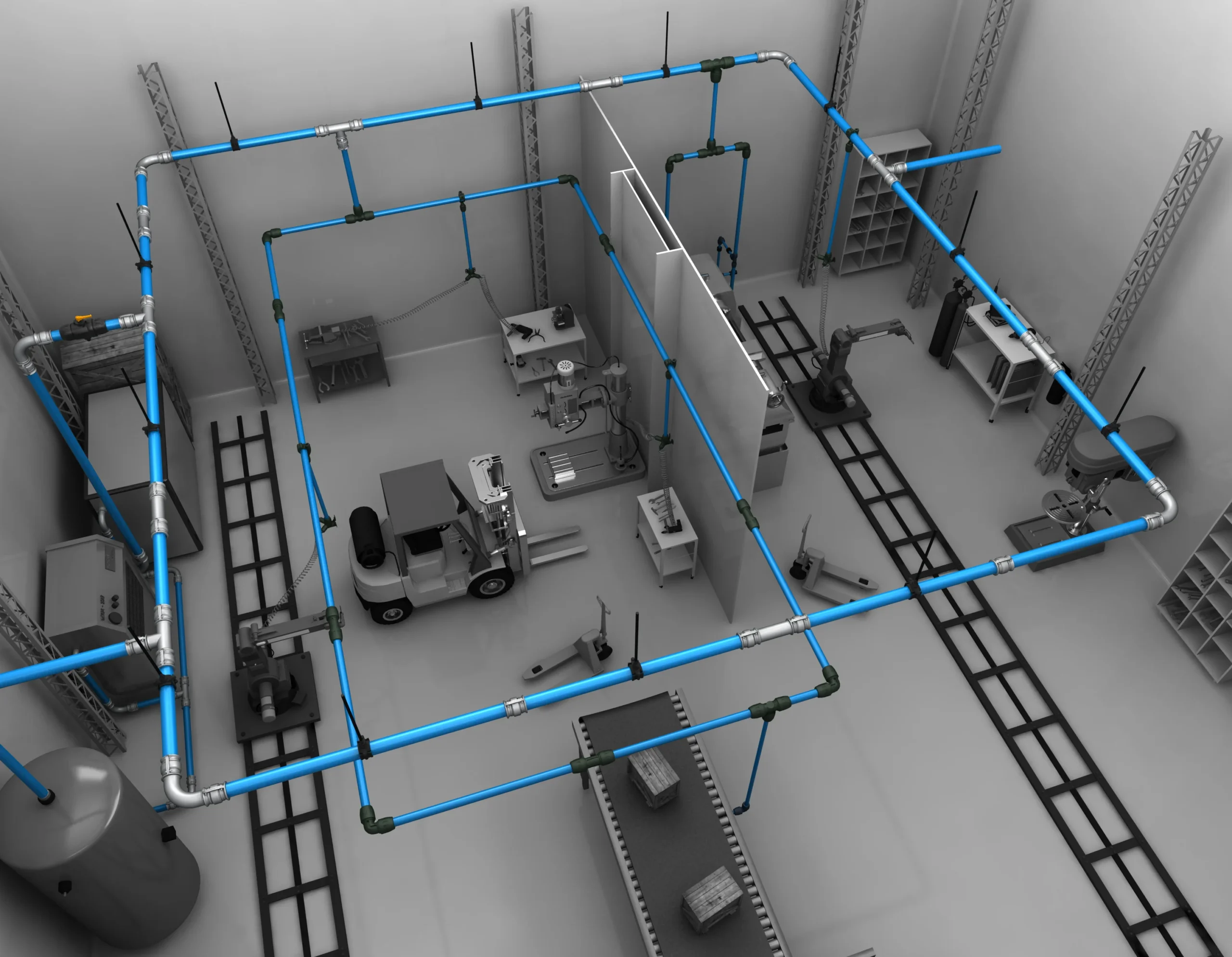

Having an efficient and reliable compressed air system in industrial facilities is critically important for energy savings and production quality. Our professional team provides customized compressed air piping design and installation services to ensure optimum performance.

For maximum efficiency and long service life in your compressed air installation, we use Parker Transair® lightweight, durable, and modular piping systems.

Parker Transair® offers lower pressure drop, easy installation, and flexibility compared to traditional steel or plastic piping systems, thanks to its advanced aluminum pipe technology. Its corrosion-resistant structure maintains performance for many years and minimizes maintenance costs. The quick connection system makes system modifications effortless, while enhancing energy efficiency and reducing operating costs. It is an ideal solution for both new installations and the modernization of existing systems.

Flameless and Gas-Free Installation: Transair’s flame-free connection method enables faster installation and eliminates harmful gas emissions, creating a safer working environment.

Improved Air Quality: Reduces particulate emissions on site.

No Power Consumption: No welding or soldering is required during installation, ensuring energy savings.

Low Carbon Footprint: The Transair aluminum piping system has five times less environmental impact compared to traditional steel piping systems.

10-YEAR WARRANTY: A 10-year warranty is provided by Transair, ensuring that even the smallest system fault is replaced free of charge.

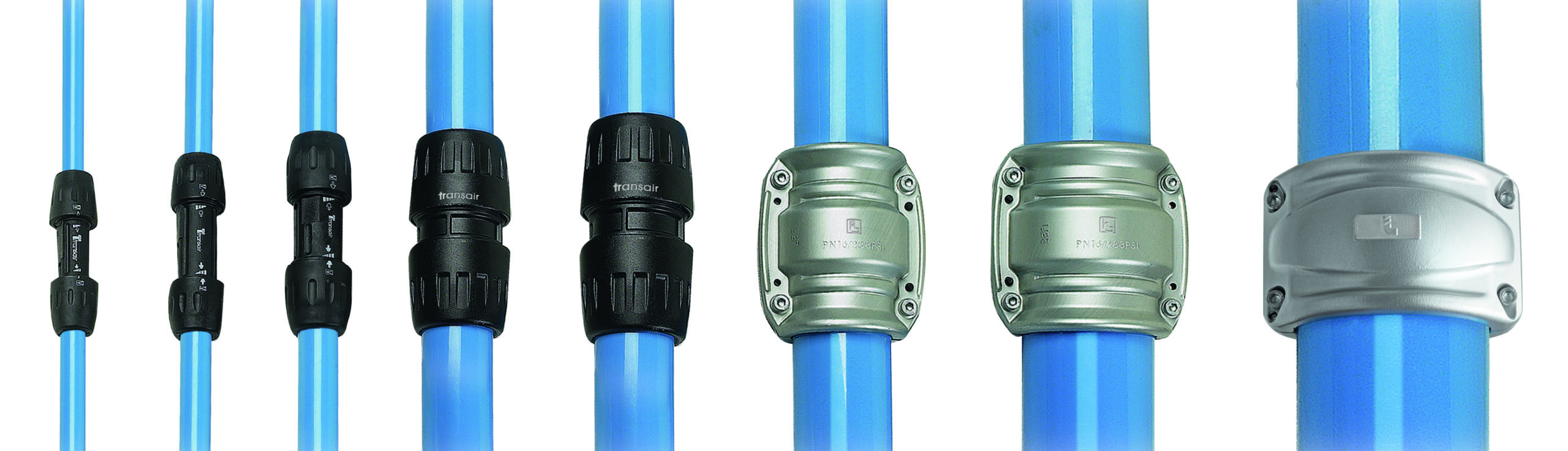

Transair® Original Modular Aluminum Piping System

Transair® has developed various technologies to meet users’ need for versatile, reliable, and safe solutions, offering the most suitable options in terms of safety, efficiency, and compatibility.

• The push‑in fitting for 16.5, 25, and 40 mm diameters offers maximum flexibility.

• The quick‑connect Spring Clip fitting for 50 and 63 mm diameters provides ease of use while ensuring the safest technology, preventing possible installation errors.

• The Clamp + Cartridge quick‑connect fitting for 76, 100, and 168 mm diameters prevents connection errors; the internal cartridge acts like a fuse in case of system malfunction leading to overpressure.

Transair® Key Features

Gases

Transair® is suitable for compressed air applications (dry, lubricated, or wet), inert gas applications such as nitrogen, argon, or CO₂ (for purity levels up to 99.99%), and vacuum applications (minimum vacuum level of 10 mbar).

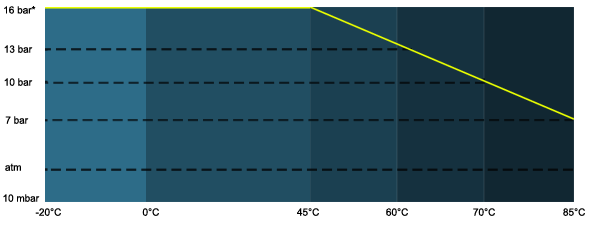

Operating Pressure and Temperature

The graph below shows the maximum operating pressure and temperature of the Transair® system.

Compressed Air Piping Installation

In all industrial facilities and many general service buildings, alongside infrastructure systems such as water and electricity, compressed air is produced, stored, treated, transmitted, distributed (and conditioned if necessary), and used within a piping system as a significant source of fluid power and a main medium for transmission or operation.

Compressed air can be considered a fluid in which energy is stored. Energy in another form is first transferred from a drive machine (electric motor, internal combustion engine, turbine, etc.) to the compressor in the form of mechanical energy. In this “work machine,” the fluid's internal energy (a form of potential or pressure energy) is generated. This energy is then utilized for various purposes, including transferring air to remote locations and converting pressure potential into mechanical energy. Throughout these transformations, “irreversibility” losses continuously occur, introducing a series of efficiency concepts.

Quick installation reduces downtime due to malfunctions. All-in-one piping solutions are tailored to meet specific customer needs for each type of pipeline. Ready-to-use products can be connected to the machine in less than 15 minutes. Its user-friendly technology minimizes the risk of error during installation. Features such as horizontal disassembly and interchangeability help reduce labor requirements.

Compressed Air System Design

After listing all compressed air users, the consumption and operating periods of each are determined. Today, compressed air is used in a wide range of industries—from printing to textiles, packaging machines to specialized assembly stations, plastic machinery to paint shops. In the catalogs of specialized machines, the required air specifications and consumption in terms of free air are usually specified. For machines where this information is not provided (typically older equipment), consumption can be determined through a simple operational test. While machines are running, their simultaneity conditions should also be confirmed by an operations specialist.

In compressed air systems with numerous users serving various purposes, the calculation of required compressed air flow must be based on a number of assumptions. Ideally, by using production procedures and figures (daily/hourly actual operating time of each pneumatic tool or air-using machine × average air consumption), total compressed air consumption per shift can be calculated.

In facilities where compressed air is primarily used for production purposes, sufficient safety margins should be considered in compressor capacity.

Additionally, especially for air-cooled, workshop-type piston compressors, 24-hour continuous operation is not recommended. To allow for maintenance and oil cooling, the capacities of such compressors should be selected with a tolerance of approximately 25% to 50%.

Frequently Asked Questions

Learn more about Compressed Air Piping Installation and Design.

A properly designed compressed air system minimizes pressure losses, increases energy efficiency, and ensures long service life for your system. It also contributes to more efficient operation of your equipment, helping to reduce maintenance costs.

During the installation process, we prefer Parker Transair® aluminum piping systems. Thanks to their lightweight and durable structure, they allow for quick installation, and their corrosion resistance ensures reliable performance for many years.

Yes, we offer modernization services to make your existing compressed air systems more efficient. With modular systems like Parker Transair®, you can easily upgrade your piping to achieve energy savings and reduce operating costs.

Aluminum piping provides high performance and energy efficiency in compressed air systems. Its modular structure and quick installation offer ease of application. Thanks to aluminum’s low friction coefficient, air flows in a laminar manner, minimizing pressure losses and increasing energy savings. Full‑bore fittings and leak‑proof design prevent air leaks, eliminating unnecessary energy loss.

In addition, aluminum does not rust and is corrosion‑resistant; no dirt or residue accumulates on its inner surface. This ensures high‑quality, clean air and extends the life of equipment such as dryers and filters. It can be used comfortably in both indoor and outdoor environments.

We Support Your Business with High-Quality Products and Services Worldwide

Optimize your operations with our compressed air solutions that adapt to evolving industrial needs, and stay ahead of the competition by increasing your efficiency.

Since 1969, our family-owned company—now in its third generation—has specialized in industrial filtration and compressed air, delivering the most reliable solutions in the industry to meet business needs at the highest level. With our Istanbul-based operations and robust logistics network, we provide fast and efficient service to customers across Turkey.

Compressed Air

Measurement, Control, and Detection Devices

Compressors

Air Treatment Units

Dust Collection Systems

Filter Group

Tepeören Mah. İTOSB 14th Street No:2 34959 Tuzla / ISTANBUL

Monday – Friday 08:30 AM – 06:30 PM

+90 216 661 40 44

[email protected]