Heat Regenerated Adsorption Air Dryer

The HRE, HRS, and HRS-L models of externally heated adsorption dryers offer versatile and extensive options in terms of variation.

The standard product range includes system solutions with capacities from 375 m³/h to 13,600 m³/h, capable of reaching pressure dew points as low as -70 °C.

Ultradryer HRE+

As with all externally heated adsorption dryers, the HRE models release the moisture—condensed in the desiccant—through a flow of heated blower air. The cooling of the desiccant is carried out using a partial flow of pre-dried compressed air. Since the cooling process is independent of ambient conditions, HRE models can be used worldwide.

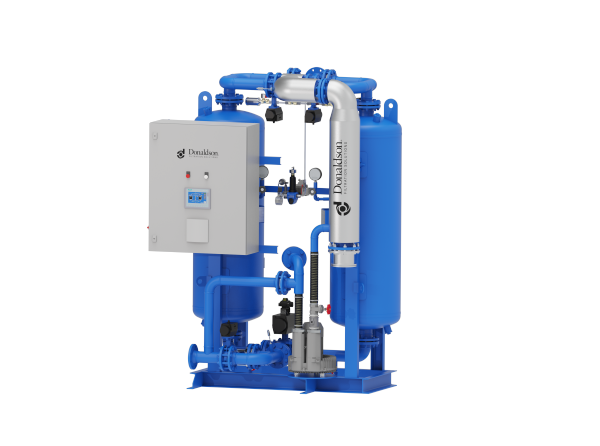

Ultradryer HRE+ Heat Regenerated Adsorption Dryer

Learn more about the Ultradryer HRE+ compressed air dryer.

Ultradryer HRE+ Air Dryer

Ultradryer HRE+ heat regenerated adsorption dryers can be used in all climate zones and offer easy maintenance with low investment costs.

As with all externally heated adsorption dryers, the desorption of the moisture adsorbed in the HRE models is carried out by a flow of heated blower air. The dryer is cooled using a partial flow of pre-dried compressed air. Since the cooling process is independent of ambient conditions, HRE models are suitable for use worldwide.

• Desorption in counterflow to the adsorption direction

• Cooling with an expanded portion of compressed air

• Designed for automatic and continuous operation

• Suitable for all climate zones

• Low investment costs

• Easy maintenance

• Chemical and electrical industries

• Mechanical engineering and plant construction

• Automotive industry

Ultradryer HRS+ Compressed Air Dryer

Learn more about the Ultradryer HRS+ compressed air dryer.

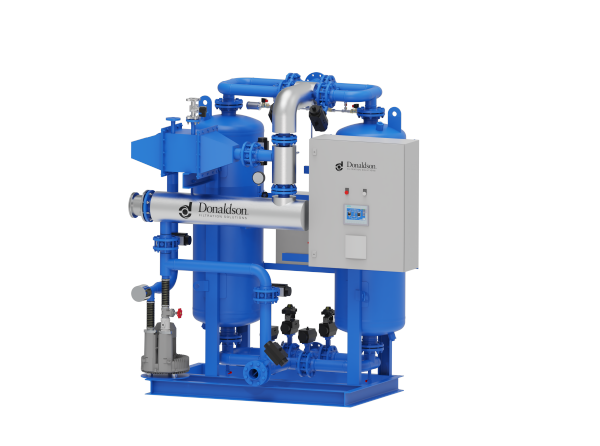

Ultradryer HRS+ Air Dryer

The HRS model of heat regenerated adsorption dryers is the most energy-efficient option, offering low operating costs and easy maintenance.

In HRS dryers, both desorption and cooling within the system configuration are carried out using ambient air drawn in by a blower. No compressed air is used during the desorption or cooling phases. Since desorption occurs in counterflow, energy consumption is minimized. Therefore, the HRS model is the most energy-efficient solution.

• Desorption in counterflow to the adsorption direction using externally heated blower air

• Cooling with ambient air

• Low operating costs

• Designed for automatic and continuous operation (up to 2,750 pressure-vacuum cycles)

• Energy savings (Zero Purge, low desorption temperature)

• Low operating costs

• Easy maintenance

• Suitable for mild climate conditions

• Chemical and electrical industries

• Mechanical engineering and plant construction

• Automotive industry

Ultradryer HRS-L+ Compressed Air Dryer

Learn more about the Ultradryer HRS-L+ compressed air dryer.

Ultradryer HRS-L+ Air Dryer

Based on the standard HRS models, the HRS-L version of heat regenerated adsorption dryers is designed to meet the requirements of tropical and subtropical environmental conditions.

Tropical and subtropical climates do not permit cooling with ambient air. The defining feature of the HRS-L models is their closed-loop cooling system (Loop Version). A water-cooled heat exchanger cools the air stream heated by the dryer. From there, the cooling air is redirected back to the inlet port of the blower.

This version provides a pressure dew point of -70 °C / -94 °F worldwide, making it suitable for all climate zones.

• Globally applicable

• Energy savings (Zero Purge)

• Low operating costs

• Easy maintenance

• Pressure dew points down to -70 °C / -94 °F

• Chemical and electrical industries

• Mechanical engineering and plant construction

• Automotive industry

We Support Your Business with High-Quality Products and Services Worldwide

Optimize your operations with our compressed air solutions that adapt to evolving industrial needs, and stay ahead of the competition by increasing your efficiency.

Since 1969, our family-owned company—now in its third generation—has specialized in industrial filtration and compressed air, delivering the most reliable solutions in the industry to meet business needs at the highest level. With our Istanbul-based operations and robust logistics network, we provide fast and efficient service to customers across Turkey.

Compressed Air

Measurement, Control, and Detection Devices

Compressors

Air Treatment Units

Dust Collection Systems

Filter Group

Tepeören Mah. İTOSB 14th Street No:2 34959 Tuzla / ISTANBUL

Monday – Friday 08:30 AM – 06:30 PM

+90 216 661 40 44

[email protected]