Air Filter

Providing clean and dry air in compressed air systems is critical for equipment safety and efficiency. Our compressed air filters remove harmful particles, moisture, and oil vapors from your system, offering long-lasting use and high performance. Designed in accordance with industrial standards, our solutions deliver reliable filtration for all types of needs and applications.

- DF Compressed Air Filter

- DF-T Compressed Air Filter

- HD High-Pressure Air Filter

- SG Compressed Air Filter

- EG Compressed Air Filter

Donaldson Ultrafilter DF Compressed Air Filter

Learn detailed information about the Donaldson Ultrafilter DF compressed air filter.

Donaldson Ultrafilter DF Compressed Air Filter

The filter design combines high performance, increased efficiency, ease of use, flexibility, and safety.

High Performance – The filter design optimized for flow, paired with innovative filtration technology, reduces pressure loss by 50% compared to traditional filters.

Safety – A unique sponge lock prevents the filter from being opened under pressure, ensuring greater safety.

Energy Savings – Timely filter element replacement leads to increased energy savings. Element replacement is determined by the Economizer, which continuously measures differential pressure. An integrated microprocessor evaluates the measured data and compares the higher energy costs caused by pressure loss with the cost of a new filter element.

Ultra Filter Compressed Air Filter - Donaldson Filter

Significant performance improvement with new filtration technology. Alongside electricity, water, and gas, compressed air is one of the most commonly used energy sources. Therefore, the following factors must be considered to obtain high-quality clean compressed air:

• Economical filtration

• Performance validated according to ISO 12500-1 standards

• Filter reliability in compliance with ISO 8573-1:2010 Compressed Air Quality Standards

The most important part of any filtration system is the filter element. The new filter material, manufactured with high production technology and optimally pleated, enhances separation and purification performance while reducing pressure loss caused by resistance by approximately 50%. The filter surface area has been expanded to retain a higher amount of contaminants.

Unrivaled high performance

The new Ultra-Filter has been developed based on worldwide experience and more efficient – economical filtration technology.

• Filter design optimized according to capacity minimizes pressure loss.

• Advanced filtration technology ensures high separation efficiency.

• Complete solution for unrivaled efficiency.

With computer-aided simulation, optimum air flow rate has been calculated, and a turbulence-free design has been applied to both the filter element and housing, thereby guaranteeing low pressure losses.

Cost savings due to energy efficiency

More economical filtration is only achievable by reducing the differential pressure created by the filter. A mere 200 mbar reduction in differential pressure allows a compressor running 8,000 hours per year to save approximately €1,500 in electricity costs. (7 bar operating pressure, 120 kW screw compressor, electricity unit price €0.08/kWh). As the example shows, the filter investment pays back in under one year.

In subsequent stages, energy savings require that filter elements be replaced at the correct time. This economic interval is calculated by an electronic component called the Economizer. Differential pressure is measured continuously, and these values are evaluated by a microprocessor, which compares energy costs with the cost of new filter elements. When the most cost-effective time for filter replacement arrives, an LED signals “Filter Change.”

Using the correct materials is also important for economical filtration. Depending on the application and required air quality, one or more of six different types of filter elements may be needed. In doing so, it is essential to keep the differential pressure to a minimum. Coarse pre‑filters, micro filters, precision filters, and activated carbon filter elements are used as required for efficient purification.

• Multiple housing sizes, element types, and accessories – offering unique, customized solutions for every application.

• Optimized flow design – 50% reduced pressure drop – minimal pressure loss, resulting in lower energy consumption compared to conventional filters.

• Performance data validated in accordance with ISO 12500‑1 (oil aerosols), ISO 12500‑2 (oil vapours), and ISO 12500‑3 (particles) – ensuring reliable compressed air filtration per ISO 8573‑1:2010.

• Filter element removable together with the filter bowl – minimizes space required for filtration installation and service.

• Code clip inside the filter housing adjustable for multiple flow directions – dual-purpose housings can serve as combination filters (inside‑out flow) or particulate filters (outside‑in flow).

• Bayonet filter bowl lock – filter cannot be opened under pressure – high safety.

• Integrated differential pressure gauge – ensures the user replaces the filter element at appropriate intervals.

• Dip‑coated housing – provides long‑term corrosion protection.

Donaldson Ultrafilter DF-T Compressed Air Filter

Obtain detailed information about the Donaldson Ultrafilter DF‑T compressed air filter.

Donaldson DF-T Compressed Air Filter

The innovative three‑stage DF‑T filter is used for the purification of compressed air and gases in confined spaces.

The unique filter element combines three separate purification stages within a single filter housing:

• Coalescing filter,

• Activated carbon adsorbent,

• High‑performance particulate filter.

This configuration provides Class 1 air quality according to ISO 8573‑1:2010. The DF‑T series is ideal as a terminal filter in applications requiring the highest quality compressed air in limited installation spaces.

The Economizer feature is integrated into the filter housing and notifies the user when it’s time to replace the filter element. Monitoring differential pressure changes and service intervals ensures the DF‑T operates at optimal performance.

This three‑stage filter can be safely used in applications up to 65 scfm at 100 psig.

• High‑performance coalescing filter, activated carbon adsorbent, and sub‑micron particulate filter combination

– Provides Class 1 compressed air quality in accordance with ISO 8573‑1:2010.

• Three‑stage purification in a single filter housing

– Saves up to 60% space and reduces installation and maintenance time.

• Economizer

– Reliably monitors filter element service life and differential pressure changes.

• Optimized flow design

– Delivers energy savings through low differential pressure.

• Bayonet locking system on the housing

– Prevents opening under pressure, ensuring high safety.

Donaldson HD Compressed Air Filter

Obtain detailed information about the Donaldson HD compressed air filter.

Donaldson HD Compressed Air Filter

Donaldson HD high‑pressure air filters offer low differential pressure at high flow rates. A wide variety of filter elements is available to meet different compressed air application requirements.

Donaldson HD housings are available in eight different sizes, ranging from ¼ in to 2 in FNPT, with pressure ratings of 64 bar (925 psig) and 400 bar (5,800 psig).

Donaldson HD high‑pressure filter housings are designed in accordance with ASME VIII, Division 1. Housings are available in aluminum, stainless steel, and carbon steel.

• Multiple material options available – aluminum, 304 stainless steel, 316 stainless steel, carbon steel (¼ in to 2 in FNPT)

• Housing design provides low pressure drop at high pressures and flow rates (925 psig and 5,800 psig pressure ratings)

• Designed in accordance with ASME VIII, Division 1

Donaldson SG Compressed Air Filter

Obtain detailed information about the Donaldson SG compressed air filter.

Donaldson SG Compressed Air Filter

Donaldson SG steel filter housings are equipped with all the features required to deliver the most efficient and cost‑effective filtration for your compressed air system.

Flanged housings provide low pressure drop thanks to an optimized flow path design. SG standard filter housings come with an Econometer differential pressure gauge and an external float drain.

For additional energy savings, Donaldson SG is also available with the optional Economizer differential pressure gauge and UFM‑D zero‑air‑loss condensate drain.

Available in three sizes covering 2,936 to 7,829 m³/h (1,728 to 4,608 scfm). Several filter element types are available to meet specific purification requirements.

Silicone‑free Compressed Air Filter

Silicone‑free steel filter housings are designed for the industrial purification of compressed air and painting‑compatible filter elements used in paint applications.

Silicone‑free SG filter housings are specifically engineered for paint industry applications – paint compatible. The housings are free from substances that could cause paint defects, ensuring that solid particles which could contaminate compressed air and gases are reliably trapped. Thanks to an optimized design, these compressed air filters deliver low differential pressures at high flow rates. A wide variety of housings with different connections is available. This product series offers 13 different housings for volume flows from 1,080 to 38,400 m³/s (at 7 bar(g) and 20 °C). The SG standard filter housing complies with the requirements of European Directive 87/404/EEC.

• Three-piece housing design – easy installation and maintenance.

• Housing structure optimized for minimal pressure loss at low flow rates – low differential pressure saves costs in compressed air and gas purification.

• Integrated microprocessor‑controlled Economizer (optional) – determines the most cost‑effective interval for filter element replacement.

• UFM‑D zero‑loss condensate drain (optional) – maximizes energy savings by allowing zero compressed air loss. It stores condensate outside the filter housing, ensuring complete removal of condensate from the compressed air.

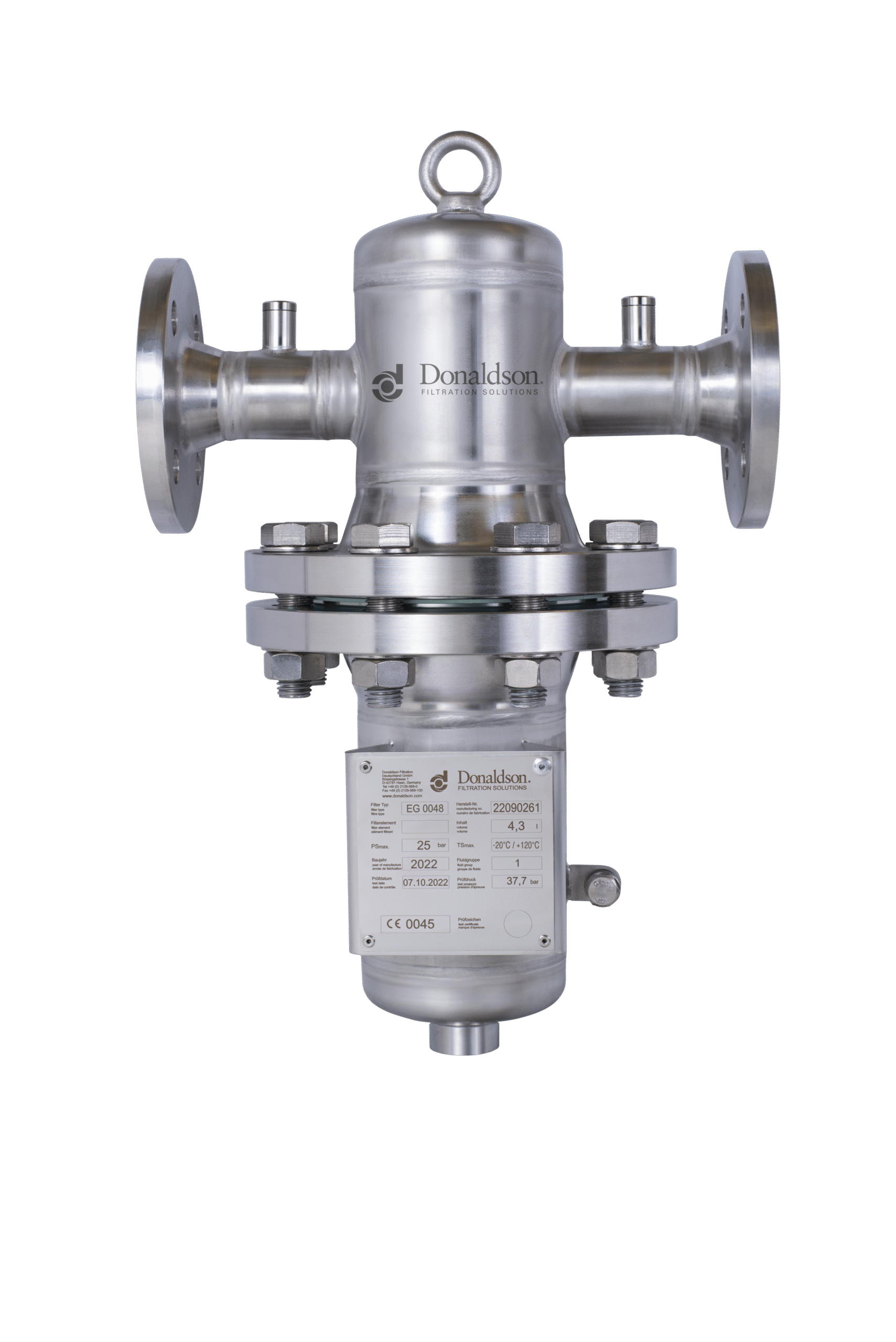

Donaldson EG Compressed Air Filter

Obtain detailed information about the Donaldson EG compressed air filter.

Donaldson EG Compressed Air Filter

Donaldson EG filter housings are designed for use across a wide range of applications for the purification of biomethane, natural gas, hydrogen, wet carbon dioxide, and similar gases.

The corrosion‑resistant housing material can be safely used at operating pressures up to 25 bar / 362 psi and temperatures from –20 °C to 120 °C (–4 °F to 248 °F).

The EG series is engineered for liquid purification of Group 1 (dangerous fluids) in accordance with PED 2014/68/EU and is developed to comply with ATEX Zone 1 and 2 requirements.

The filter housing design accommodates various types of coalescing, particulate, and carbon filter elements while ensuring high retention efficiency at low differential pressures.

• Corrosion‑resistant stainless steel housing structure

• Designed for 25 bar operating pressure and a temperature range of –20 °C to 120 °C (–4 °F to 248 °F)

• Use of conductive materials suitable for explosive atmospheres, including ATEX Zone 1 and 2

• Inlet and outlet flange connections ensure leak‑tight performance

• DF connection system provides perfect alignment between the filter element and housing, delivering high filtration performance at low differential pressures

We Support Your Business with High-Quality Products and Services Worldwide

Optimize your operations with our compressed air solutions that adapt to evolving industrial needs, and stay ahead of the competition by increasing your efficiency.

Since 1969, our family-owned company—now in its third generation—has specialized in industrial filtration and compressed air, delivering the most reliable solutions in the industry to meet business needs at the highest level. With our Istanbul-based operations and robust logistics network, we provide fast and efficient service to customers across Turkey.

Compressed Air

Measurement, Control, and Detection Devices

Compressors

Air Treatment Units

Dust Collection Systems

Filter Group

Tepeören Mah. İTOSB 14th Street No:2 34959 Tuzla / ISTANBUL

Monday – Friday 08:30 AM – 06:30 PM

+90 216 661 40 44

[email protected]